What is Rockwool?

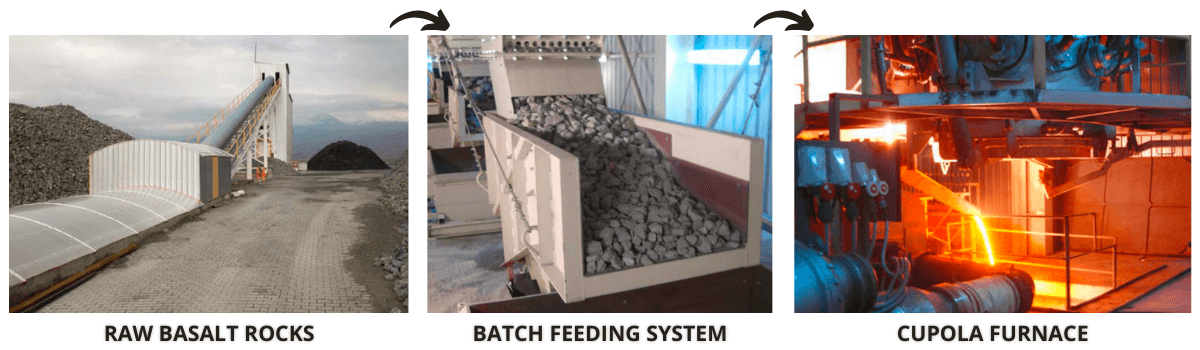

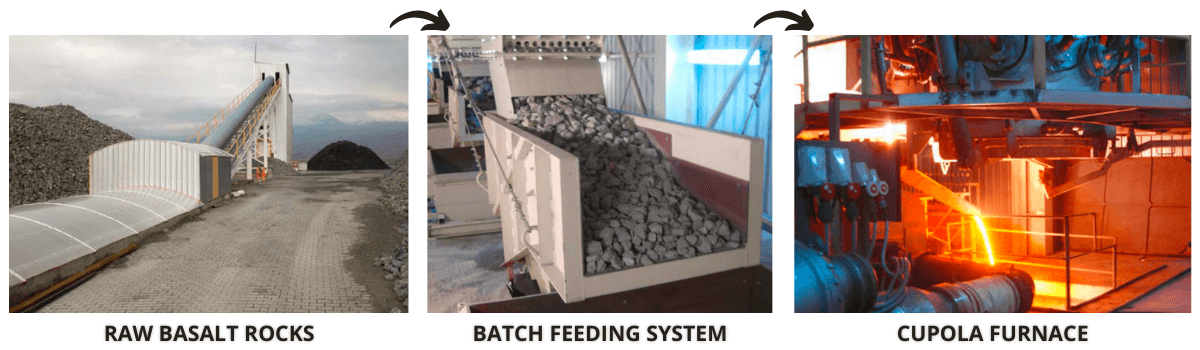

Rockwool was originally developed as an insulating material. Research starting in the 1960s in Europe, looked at converting this material as a suitable growing media and its usefulness in the botanical industry has been expanding ever since. Functionally very similar to fiberglass, it is made by heating up basalt rock and chalk to a temperature of up to 3000 degrees F (1650 C) converting it to lava. The lava is then cooled and spun into fibers.

The spun fibers are then mixed with a binding agent. The resulting product is then formed into mats, slabs, blocks, or cubes which can be used horticulturally and primarily in hydroponic production. They can be used for starting seeds, growing vegetative and fruiting crops, both short and long-term. Because of the high temperatures used in the manufacturing process, rockwool products are biologically inert, even though they are made from natural materials.

Benefits of Using Rockwool

Rockwool is a versatile growing media with lots of advantages over other options. It is lightweight, so it is easy to handle and store. Its structure discourages overwatering and root hypoxia (lack of oxygen). Rockwool is great for hydroponics. It is not only safe for hydroponic use, but it also has many advantages for hydroponic production. Its structure is well-suited to hold moisture. This means once it has been ideally saturated, it tends to stay in place. This stability is important for any system that has flowing water.

The consistent structure of rockwool products takes away some of the guess work of growing. You know what you are getting once you have used them. Rockwool is up to 96 percent porous. Except for peat moss, this is higher by farm than almost any other growing media such as coir, perlite, or vermiculite. The porosity of rockwool allows for the free flow of nutrients, water, and air. Root hairs and fibers have plenty of places to go, encouraging their development in rockwool media. Mycorrhizae also has been shown to proliferate in rockwool substrates. Being made of stone, rockwool does not break down over time and has the potential to maintain its structure for repeated usage for a very long time.

Rockwool products are sterile. This means that there is no initial possible contamination or introduction of bacteria, viruses, or other pests to the growing system. Beneficial microbial products can be added to rockwool cubes and strata as the myriad channels within each block or cube allow for the sustained development of these beneficial organisms. The free flow of oxygen within rockwool cubes helps to encourage this growth once established.

Germination rates are higher in rockwool cubes than some other substrates. In a 2017 study comparing rockwool cubes to cotton and sponge as other soilless media options for hydroponics, rockwool came out on top. Plants seeded in the rockwool cubes produced 70 percent germination rates as compared to the other two media that each averages a 50 percent germination rate. Crop yields have been shown to be higher in rockwool media versus other media as well.

In a 2015 study comparing yields of lettuce crops found rockwool to be superior to the compared substrates of peat moss and coconut coir. Total yield, marketable yield, and weight were all higher using rockwool blocks too. For total yields of lettuce per square meter in this study, rockwool averaged 5641 grams compared to 4564 grams in peat and 3969 grams in coir. Marketable yields followed suit at 5019 grams versus 3957 grams in peat and 3285 grams in coir. The average weight per head for lettuce grown in rockwool was 313.5 grams compared to 242.9 grams in peat and 216.4 grams in coir.

Rockwool products also do not have an appreciable effect on the EC, pH (once the initial soaking is done) or action of nutrient solutions that flow through them. What you put into your hydro system or nutrient reservoir is what you get. This means that growers can respond quickly to noted deficiencies and do not have to account for the media absorbing or blocking any nutrient uptake. This is due to the lack of Cation Exchange Capacity (CEC). This means that nutrients remain in whatever form they are submitted into the system. Unlike other media, rockwool will maintain whatever EC level is present in your solution. This also makes it easier to leach out nutrient excesses when discovered as rockwool will not hold on to nutrients.

How to Use Rockwool Cubes

Rockwool cubes can be used for direct seeding, propagation by cuttings or transplanting. Plants can spend their entire lives in rockwool cubes or be transplanted from them into other growing media or containers. The plants need not be removed from the rockwool cube, but cube and all can be transplanted into its new home. This is far less disruptive for the plant and allows it to acclimate to its new home more quickly.

Rockwool cubes, as well as all rockwool products, are not like other grow media. Unlike other grow media, growers that use rockwool products have much more control over what goes into their plants’ root zones. They can control nutrient and moisture levels more easily than with other media. This is a plus for deliberate and conscientious growers. It does mean though that actions intended to remediate need to take place quickly once problems are discovered though. Conversely it means that additive nutrients can take effect more rapidly when introduced to the system. Growers can steer their plants more easily towards vegetative or flowering/fruiting growth depending on nutrient values and how they are adjusted.

Rockwool starts out more alkaline than most other grow media (see below). This means that there is an extra step needed before it can be used for most crops and most growing systems. Also, EC levels should be checked more often when using rockwool as they are more prone to rapid fluctuation when other factors are introduced (such as temperature increases, etc.) in rockwool media.

How to Water Rockwool Cubes

Unlike some other media, rockwool is not ready to use “right out of the bag.” Because the pH of rockwool at the outset is too high for almost all crops, it will need to be lowered. pH levels that are too high (too low as well) will block the uptake of important nutrients to your plants, even if they are otherwise available. Premoistening your cubes or blocks in distilled or deionized water for at least a full day before use will neutralize the pH and allow the rockwool to be able to imbibe moisture for your plants. Place them in your hydro system and allow them to sit for another full day. Test the pH of the water before using. If the pH is still too high, remove the rockwool blocks and soak them again in the pH neutral water. You should obtain a stable reading between 5.5 and 6.5 before starting or transplanting any plants into your cubes.

Once your rockwool cubes have been properly premoistened and buffered, they are ready for use. It takes some trial and error to learn how much irrigation and flow to allow to your rockwool media. Rockwool media supports plant growth best when not submerged constantly in water, but rather with ebb and flow systems, where nutrient solution wash over the media intermittently. This allows for some drainage in between waterings, but still allows the media to hold on to some amount of the nutrient solution in between waterings for the plant to feed on. This type of grow system allows the EC to stay stable as well.

Growers used to other types of media or hydroponic systems where water continually runs, will need to adjust their practices. Experience growing in media such as perlite, clay or coco is different than growing in rockwool. To successfully grow in rockwool and to take advantage of all its benefits, growers will need to adapt to the distinctive needs of rockwool grow culture. Rockwool has up to a 91 percent water-holding capacity. Higher by far than other commonly used substrates for hydroponics, including coir, vermiculite, perlite, peat, charcoal, sawdust, or clay pebbles.

Reusing and Sterilization of Rockwool

As mentioned, one of the great things about rockwool is that it is a reusable growing media. This not only has environmental benefits, but financial ones as well. Reusing your rockwool cubes must be done carefully and thoroughly though in order to not potentially contaminate your new crop with any biological residue or pathogens from your last one.

Heat is the best thing to use to treat your rockwool cubes or slabs before reusing. This can be accomplished by using steam, or at the very least, boiling water. The cubes can be submerged right into the water or steam “bath” or the steam or boiling water can be directly applied to the rockwool, depending on your setup. This process will also help to leach out any salt buildups that may have set in over the course of crop production.

There are commercially available cleaners and solvent that can be applied to rockwool between uses. These vary in efficacy, but regardless, if these are selected for use, it is imperative that they be thoroughly rinsed out before reusing, lest there be any chemical residue in your rockwool cubes that will contaminate or harm your successive crops.

While it can be reused multiple times, there is a point of diminishing returns when it comes to reusing rockwool products. They cannot be used indefinitely. While it will vary from grower to grower, crop to crop, after about an average of 6 uses, your rockwool media should be retired. They do not however, need to go into the landfill. They can be shredded and incorporated into other growing media. They could also be incorporated into the soil for outdoor crops. Either way, they should still be sterilized before being “put out to pasture” so as not to potentially spread contaminants.

Other Consideration for Rockwool Use

Rockwool is a unique growing media with properties unlike other, typical, grow media. Individuals with sensitive skin should use gloves when handling it. If you have had any issues handling fiberglass insulation, then you should assume the same issue will ensue during and after handling rockwool products. If handling rockwool for prolonged periods, or when it is dry, goggles and/or a face mask are advisable as well, as the dust from it can be an eye irritant also.

If rockwool cubes should get too wet or need to be leached out, it is important to remember not to squeeze them. Squeezing them to wring them out will compress the fibers and impede their ability to allow the free flow of water and air that make rockwool such a useful media for hydroponic growing. It is better to remove them from the hydro system, flush them with pH neutral water and shake off the excess moisture.

Why Cultiwool Products?

While there are several companies out there that produce rockwool growing media, Cultiwool (A.K.A. Cultilene) should be considered as the premier option. They have been in the business of producing horticultural grade rockwool products for over forty years. With their commitment to sustainability and to challenge existing technology, they focus on forging international partnerships to combat the global problems surrounding food shortages and the sustainable production of nutrient-dense foods. Their commitment to the environment through their corporate social responsibility efforts has shown them to be a world leader among other similarly poised rockwool producers such as Grodan. Cultiwool’s business practices evince their focus on water and energy conservation, as well as their initiatives to recycle, encouraging all members of their supply chain, from the raw material producers to the assembly line workers all the way to the end consumer user to do so responsibly.